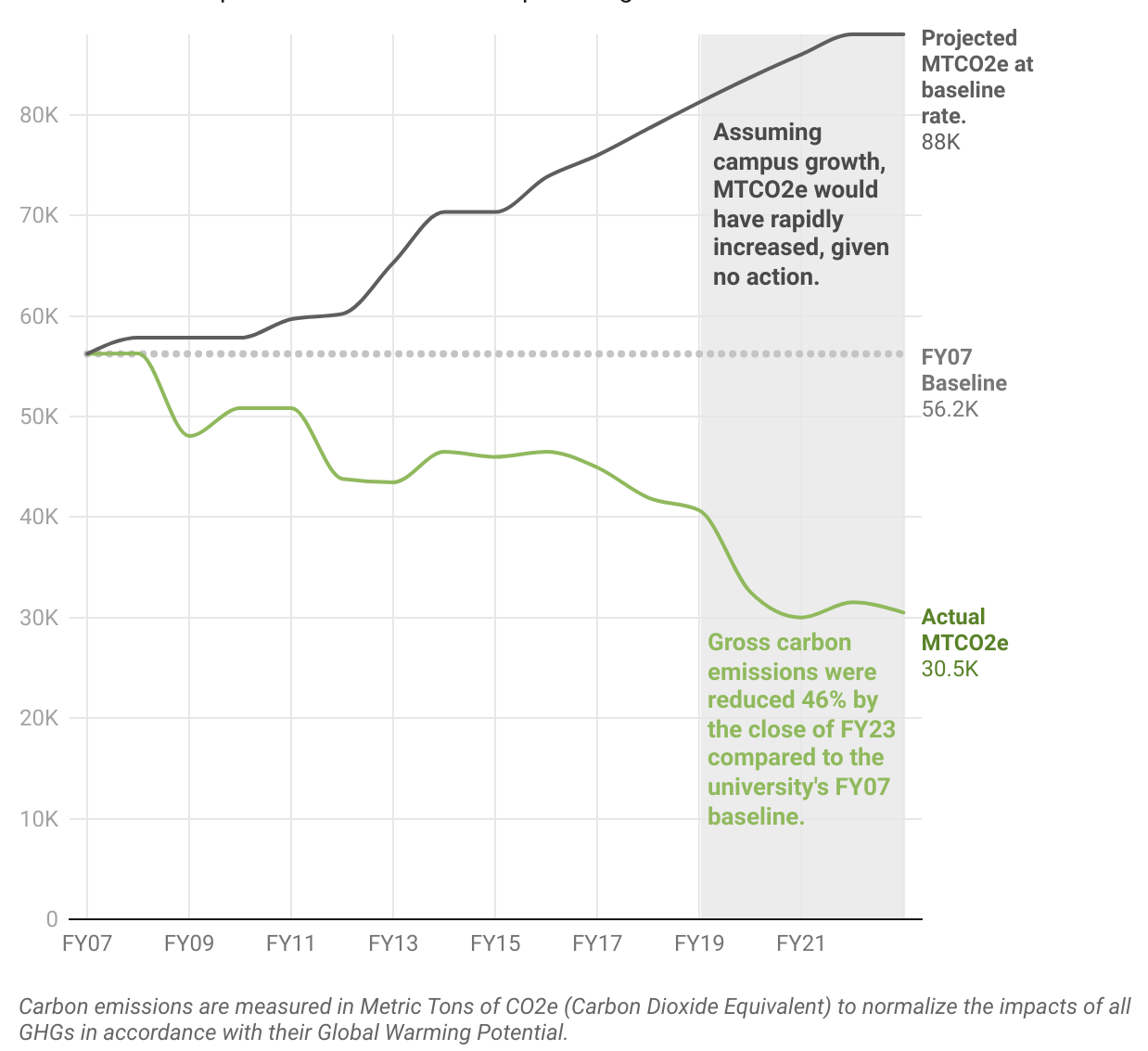

Phase I Summary: Reducing GHG emissions through energy efficiency measures, building renewal, and a commitment to adaptive reuse has had a significant impact on the university’s path to neutrality. From an FY07 baseline, the in-house Utilities Operations team in Facilities & Campus Services achieved a 46% reduction in total GHGs from operations by the close of FY23, even as the campus footprint grew by 56% over that same timeframe. Continued investment and assessment of areas for improvement in the efficiency of our operations is ongoing.

Energy Use Intensity and GHG Emissions Reductions To Date

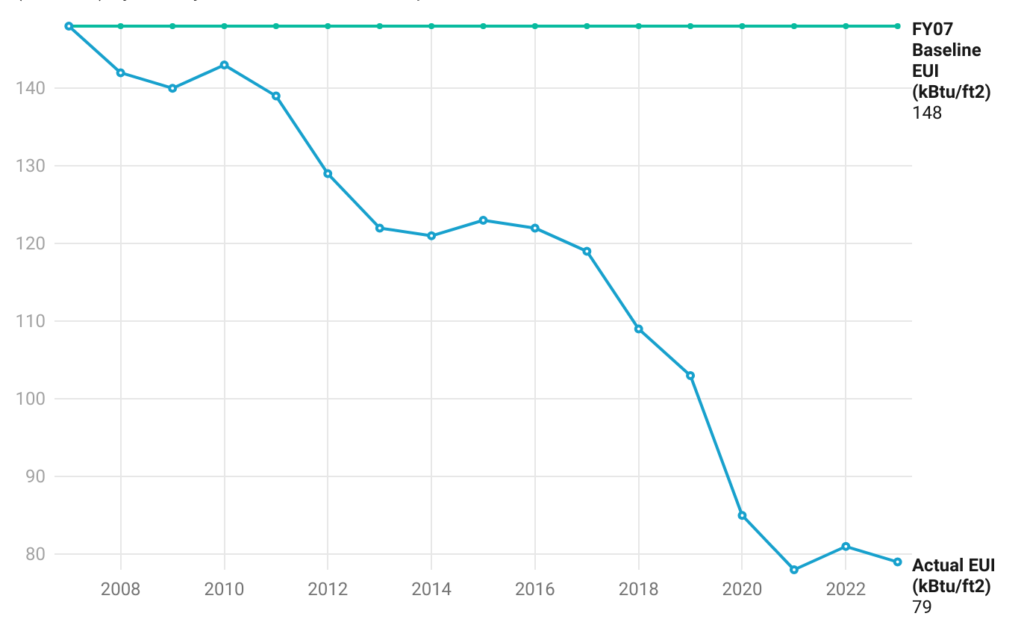

Energy use at the building level, defined as kBTUs (Kilo British Thermal Units) per GSF (Gross Square Feet), is a strong indicator of efficiency in operations. The energy use intensity (EUI) metric tells us how efficiently campus buildings are performing. Through continuous investment in energy efficiency, including building automation systems (BAS) and advanced scheduling, Wake Forest’s in-house F&CS Utilities Operations team has achieved a 47% reduction in EUI from the FY07 baseline (Figure 1.1).

Figure 1.1 WFU Energy Use Intensity kBtu/GSF Building Space

Energy use Intensity is a strong indicator of efficiency in operations. Through continuous conservation and efficiency efforts, WFU has collaboratively reduced its total energy use per square foot (kBtu/ft2) by 47% compared to its FY07 baseline.

Figure 1.2 WFU Gross Carbon Emissions Reductions

The university’s gross carbon emissions have declined by 46% over the same timeframe, even as gross square footage has more than doubled to over 5.6 million gross square feet (Figure 1.2). This consistent downward trajectory puts Wake Forest ahead of schedule to meet its benchmark goal of a 50% reduction by 2030.

Retrofits and Building Renewal

Increasing efficiency in the university’s buildings and systems directly results in decreased GHG emissions. Wake Forest’s commitment to preserving and retrofitting campus buildings has resulted in over 20 past projects with energy savings totaling over 5 million kilowatt (kW) hours. The renovations to the Hearn Plaza residence halls, for instance, increased energy efficiency in these buildings by over 20%, and water efficiency by 40%.

On average, renewing existing buildings on campus saves between 50 – 75% of the embodied materials, energy, and equivalent carbon. By adapting existing buildings on campus to serve contemporary needs, we are able to cut operating costs and make better use of existing spaces. This effort includes renovating and equipping existing spaces with the latest resource-efficient fixtures, including: low-flow toilets and showers, LED lights, and remotely monitored temperature regulation systems. Ninety percent of Wake Forest’s outdoor and pedestrian lights have been converted to LEDs. And over 450 meters across 175 buildings on Wake Forest’s property provide data that allow for detailed monitoring and inform future efficiency planning.

New Construction and Major Renovation

Wake Forest’s Green Building policy states that all new buildings — including major renovations as well as new construction — must be designed and built to meet a minimum of the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED) Silver standards. A list of LEED-certified buildings and their scorecards is available here.

District Heating & Cooling

District heating and cooling systems offer an efficient way to generate steam and chilled water centrally and to circulate the utilities to buildings across campus.

At Wake Forest, chilled water is produced in two campus locations and distributed underground to dehumidify and cool our buildings. The 2018 replacement of the North Chiller Plant has nearly doubled chilled water capacity in that plant and increased efficiency by 16%. The additional optimization of systems at both North and South Chiller plants in 2018 led to an overall system efficiency increase of nearly 25%. A renewal and expansion of the South Chiller plant is underway, and is expected to be complete in spring 2025. The project includes the replacement of aging equipment, expansion of cooling capacity to address current and future campus cooling needs, and implementation of new technologies and controls strategy for significant cost savings and efficiencies.

Steam for heating and hot water is also produced centrally on campus and distributed to campus through over a mile of insulated pipes and utility tunnels. In 2023, the Worrell Boilers that were at the end of their lifespan were replaced with new condensing hot water boilers. These new boilers have yielded notable efficiency gains, resulting in reduced energy consumption and decreased operating costs. The project also involved the renewal of aging underground piping, enhancing the reliability of heating infrastructure.

The two central boilers of the University Operations Center are original to campus and have served campus needs for over 70 years. A third boiler was added in 2013 and is a fire tube with 20,000 lbs per hour capacity. A fourth boiler was added in 2019 with equal capacity to Boiler 3. Boiler number two is at the end of its lifespan, and will be replaced in the coming years with another fire tube boiler that will allow for better heat transfer and efficiency.